Aluminum-Scandium Alloys, a Promising Future

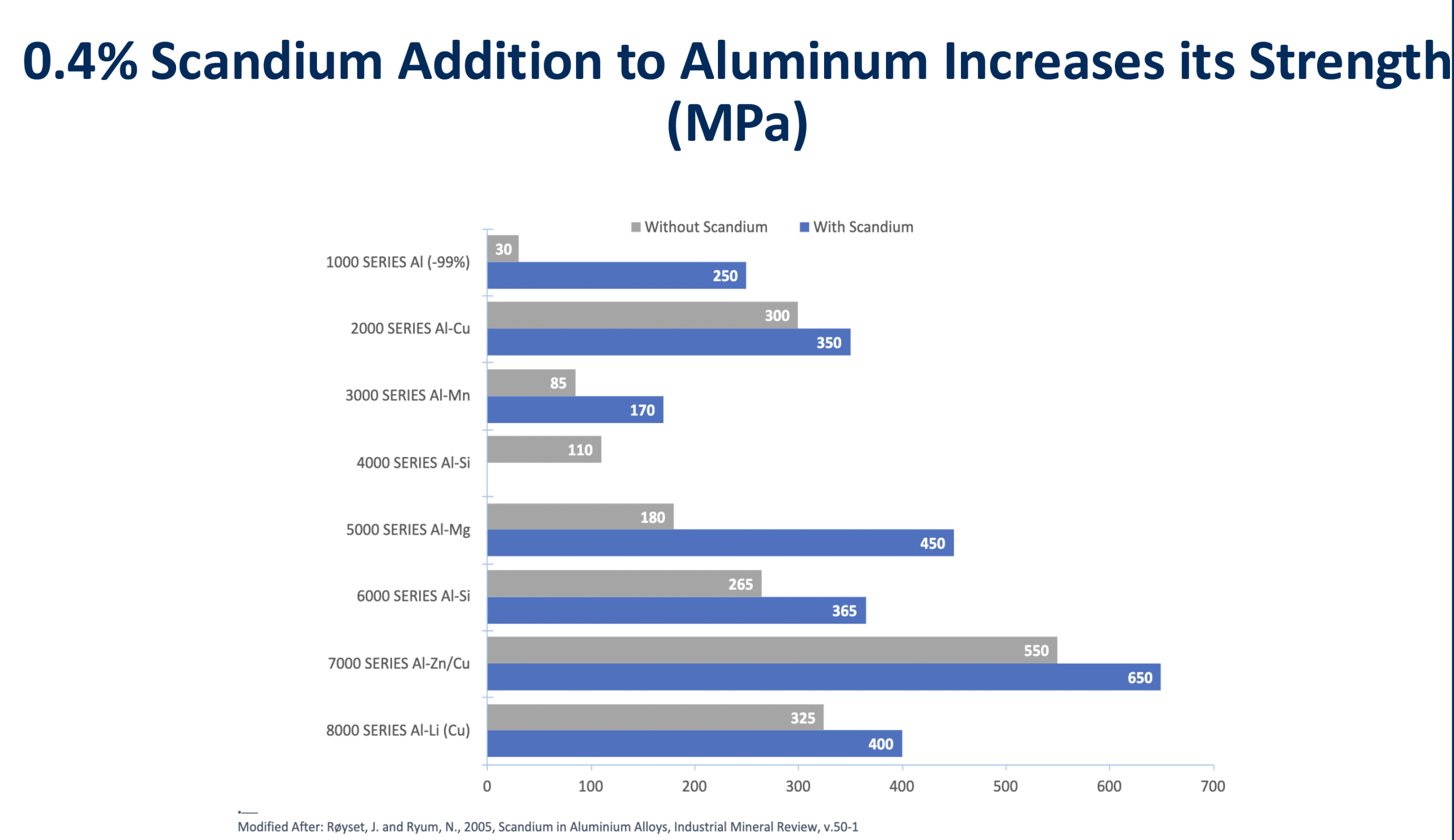

Scandium+ is dedicated to the research, development, and commercialization of innovative scandium uses. We strive to unlock the full potential of scandium through strategic partnerships, cutting-edge technology, and a commitment to responsible stewardship, leading progress across multiple sectors. To address the urgent need for lightweight and high-performance materials, Al-Sc alloys offer competitive solutions in vital sectors:

- Aerospace & Space: Optimization of structural weight while maintaining mechanical properties.

- Automotive & Mobility: Reduced energy consumption thanks to lighter components.

- Defense Industry: Enhanced performance of strategic equipment.

- Renewable Energy: Development of more efficient solutions for wind and solar.

- 3D Printing: Additive manufacturing with materials offering unmatched mechanical performance.

3D Printing

Aircraft Parts

Electric Motor Wires

Heat Exchanger

Scandium Canada has developed two aluminum-scandium (Al-Sc) alloys, AA7075 and A535, along with their powders, initially intended for additive manufacturing (3D printing) applications. This work, carried out in collaboration with McMaster University, Ontario, Canada, has resulted in a significant body of intellectual property.

The integration of these materials into 3D printing, in particular, represents a major breakthrough for industries such as aerospace, automotive, and additive manufacturing. These two alloys are the subject of a provisional patent application filed with the United States Patent and Trademark Office in September 2024, entitled: “Aluminum alloy powders for additive manufacturing. Methods of producing the same and uses thereof.”

Scandium+ is committed to the commercialization of all forms of aluminum scandium, beginning with the pre-commercial launch of its Al Sc powders for 3D printing, as well as the development of new high-performance alloys for use across all economic sectors.

Our Commitment: Deliver revolutionary, lightweight, ultra-durable materials to all industries.

Patent Pending: In September 2024, the company filed a provisional patent application with the U.S. Patent and Trademark Office for two Al Sc alloys dedicated to 3D printing. A PCT filing followed this first filing in September 2025 to assert worldwide priority.

Strategic Positioning: Scandium Canada’s alloys are aluminum variants modified with scandium and other metals, designed to address the deficiencies of aluminum alloys currently used in aerospace, automotive, and military applications.

The result: either lighter parts with equivalent mechanical properties or parts of equal weight with enhanced performance.

SHORT TERM GOALS

- Development of a replacement matrix to identify the products and manufacturers that would benefit most from the mechanical properties of the company’s two Al-Sc alloys, enabling efficient and targeted pre-commercialization efforts for products that can reach the market in the short term.

- Prototyping of parts for the aerospace and automotive sectors.

- Prototyping of frames for photovoltaic cell assembly.

- Prototyping of replacement parts for heat exchangers.

- Prototyping of welding wires.

- Various R&D collaborations with universities and researchers in Canada and abroad.